3D printing, also known as additive manufacturing, has emerged as a groundbreaking technology that is transforming the way we design, manufacture, and interact with physical objects.

From creating intricate prototypes to producing customized medical implants, 3D printing has opened up a world of possibilities across various industries.

What is 3D Printing?

At its core, 3D printing is a process of creating three-dimensional objects by adding layers of material upon each other based on a digital design.

Unlike traditional subtractive manufacturing methods, where material is removed from a solid block, 3D printing builds objects from the ground up, layer by layer. This additive approach offers several advantages, including:

- Design Freedom: 3D printing allows for the creation of complex geometries and intricate designs that would be impossible or extremely difficult to achieve with traditional manufacturing techniques.

- Customization: 3D printing enables the production of customized products tailored to specific needs and requirements. This is particularly valuable in fields like healthcare, where personalized medical devices and implants are crucial.

- Reduced Waste: By building objects layer by layer, 3D printing minimizes material waste compared to subtractive manufacturing methods that often involve significant material removal.

- Rapid Prototyping: 3D printing allows for the rapid creation of prototypes and models, enabling designers and engineers to test and refine their designs quickly and efficiently.

- On-Demand Manufacturing: 3D printing facilitates on-demand manufacturing, allowing for the production of parts and products as needed, reducing the need for large inventories and long lead times.

How Does 3D Printing Work?

The 3D printing process typically involves the following steps:

- Design: The process begins with creating a digital 3D model of the object using Computer-Aided Design (CAD) software. This model defines the shape, dimensions, and other features of the object.

- Conversion: The 3D model is then converted into a format that the 3D printer can understand, typically an STL (Stereolithography) file. This file format represents the object as a collection of interconnected triangles.

- Slicing: The STL file is sliced into thin layers by specialized software. These layers will be sequentially printed to build the object.

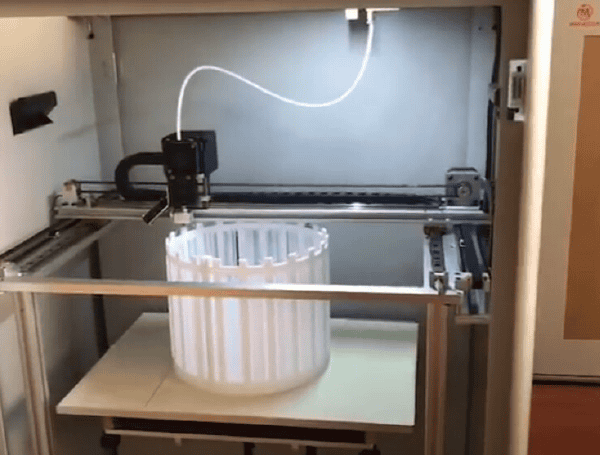

- Printing: The 3D printer reads the sliced data and deposits or solidifies material layer by layer according to the design. The specific printing method varies depending on the type of 3D printer being used.

- Post-Processing: Once the printing is complete, the object may undergo post-processing steps such as removing support structures, cleaning, sanding, or painting, depending on the desired finish and application.

Types of 3D Printing Technologies

There are various 3D printing technologies available, each with its own strengths and limitations. Some of the most common types include:

- Fused Deposition Modeling (FDM): This widely used technology involves extruding a thermoplastic filament through a heated nozzle, melting the material and depositing it layer by layer to build the object. FDM is known for its affordability and ease of use.

- Stereolithography (SLA): SLA uses a UV laser to cure a liquid resin, building the object layer by layer. SLA offers high precision and smooth surface finishes, making it suitable for intricate designs and prototypes.

- Selective Laser Sintering (SLS): SLS employs a high-powered laser to fuse powdered material, such as nylon or metal, layer by layer. SLS is known for its ability to create strong and durable parts with complex geometries.

- Digital Light Processing (DLP): Similar to SLA, DLP uses a projector to cure a liquid resin, but instead of a laser, it uses a digital light source to project the entire layer at once. DLP offers faster printing speeds compared to SLA.

- PolyJet: PolyJet technology jets droplets of photopolymer that are UV-cured to create smooth, detailed prototypes, parts, and tooling. It can print in multiple materials with different properties, colors, and hardnesses.

Applications of 3D Printing

3D printing has found applications in a wide range of industries, including:

- Healthcare: 3D printing is used to create custom prosthetics, implants, surgical guides, and anatomical models for pre-surgical planning.

- Aerospace: 3D printing enables the production of lightweight and complex components for aircraft and spacecraft, reducing weight and improving fuel efficiency.

- Automotive: 3D printing is used for rapid prototyping, tooling, and even the production of end-use parts for vehicles.

- Consumer Products: 3D printing is used to create customized products, such as jewelry, footwear, and eyewear, offering personalized designs and on-demand manufacturing.

- Architecture: 3D printing is used to create scale models, architectural components, and even entire buildings, offering new possibilities for design and construction.

The Future of 3D Printing

As 3D printing technology continues to evolve, we can expect to see even more innovative applications and advancements in the future. Some of the key trends include:

- Increased Accessibility: 3D printers are becoming more affordable and user-friendly, making them accessible to a wider range of users, including hobbyists, educators, and small businesses.

- New Materials: Researchers are constantly developing new materials for 3D printing, expanding the range of applications and enabling the production of objects with specific properties and functionalities.

- Bioprinting: Bioprinting, a specialized form of 3D printing that uses biocompatible materials and living cells, holds the potential to revolutionize healthcare by enabling the creation of tissues, organs, and other biological structures.

- 4D Printing: 4D printing involves creating objects that can change shape or properties over time in response to external stimuli, such as temperature or light. This technology has potential applications in fields like robotics and self-assembling structures.

3D printing is a transformative technology that is reshaping the manufacturing landscape and opening up new frontiers in design, innovation, and production.

With its ability to create complex geometries, customize products, and reduce waste, 3D printing is poised to continue its revolutionary impact across various industries, driving progress and shaping the future of how we create and interact with the physical world.

Please make a small donation to the Tampa Free Press to help sustain independent journalism. Your contribution enables us to continue delivering high-quality, local, and national news coverage.

Connect with us: Follow the Tampa Free Press on Facebook and Twitter for breaking news and updates.

Sign up: Subscribe to our free newsletter for a curated selection of top stories delivered straight to your inbox.